- Independent suspension (who doesn’t want this?)

- All wheel/four wheel drive

- Real working steering wheel mechanism

I later added one other thing; Power Functions.

By the way, the last time I played with Lego, there was no such thing as studless Technic bricks. But it didn’t take me long to get familiar with it. I have to say, the studless system has its limitation but the advantage is far greater, the best being everything is simply multiple of 1 unit.

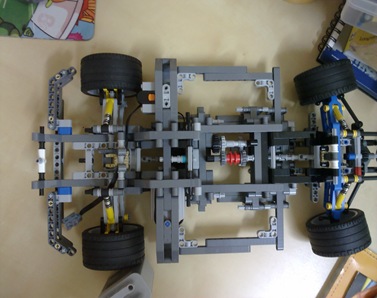

Anyway, coming back to my effort, here’s a picture of my first attempt at building a car:

Overall, it’s very flaky. The only part of the car that is good is the rear as I spent days working on it. The mid and front part, took me only half a day because I was so eager to get this thing moving. And it did. Well, partially anyway. As you can see on the top right of the photo, the Power Functions’ battery pack is on and I have one XL motor in it, so this baby can move, but only forward and backward because, if you look closely, the steering is not done yet.

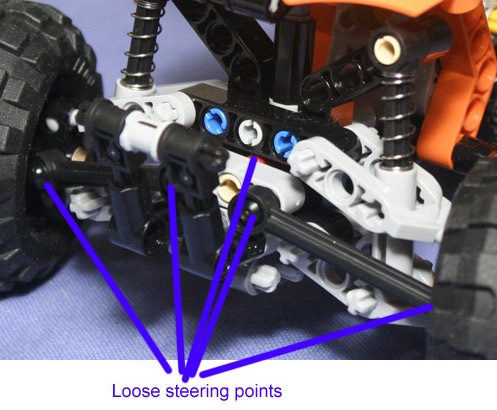

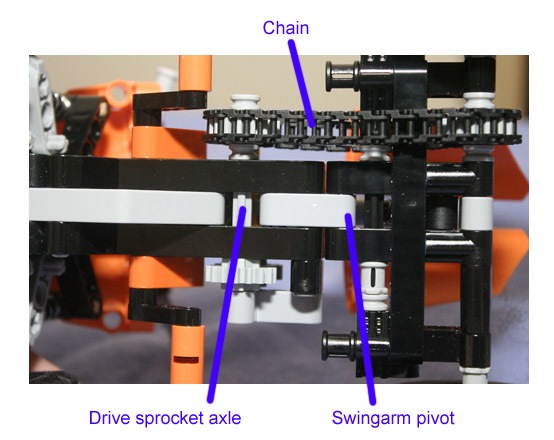

Here’s a few more photos:

So, what have I learned so far?

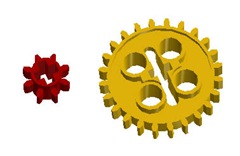

1. If you have a heavy model, don’t use bevel gears in perpendicular setup to transfer power from motor to gear box. If you do, at least make sure if you have enough counter gears, because under high stress, the driver gear will jump a tooth or two before the follower follows. The better option is to use knob wheels.

|  |

No.

|

Yes.

|

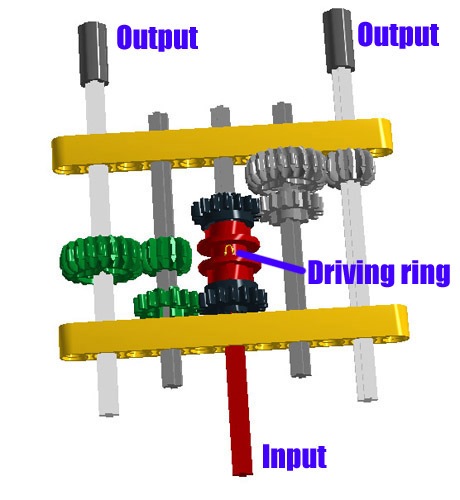

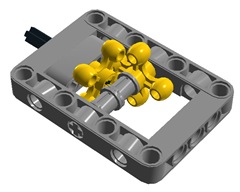

2. More gears is better. Yes, more gears will introduce more friction and as such will lose efficiency, but what I've found, using more gears will provide higher durability and add some needed sturdiness. Example shown below. Originally, the drive shaft connects directly to the input gear of the differential via a universal joint. Simple, yes. Durable, not. In the setup shown below, redundant gearsets are used and I've found them to be much better and more reliable at transferring power to the differentials.

3. Use shorter shafts where ever possible. Lego, as you might have been aware, are made of plastic. So, the longer axles are somewhat prone to torsion effect. Another way to counter torsion effect is to again use redundant gearsets that are spread apart along the axle.

After a ‘successful’ run, I have taken my model apart to fix known issues, and hopefully, the second version will be much better. I’ll report back soon.

-Wan Khairil Reza-