Last weekend I took to myself to design my very first Lego Technic gearbox. I set a simple goal; a two-speed gearbox with 1 input axle, 1 output axle, and no gear grinding allowed.

I'm still at the very early stage engaging in this Lego Technic hobby and I'm only beginning collecting my Technic parts. As such, unfortunately, I don’t have enough parts available to build an actual Technic gearbox. Luckily, Lego provides a useful tool to help people virtually design their Lego projects. It is the Lego Digital Designer (LDD) and it is downloadable totally free from Lego's website. Even though LDD is not as flexible as I wish it could be but it is good enough for most design tasks. The learning curve is not steep, provided you have some foundation in Lego building. Good mouse dexterity would come in handy as well.

In this blog post I want to share my process in designing my gearbox, using LDD for now and hopefully with actual Lego Technic parts soon.

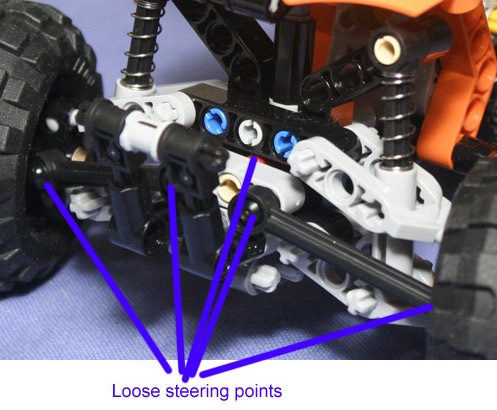

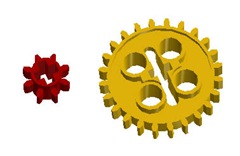

First, being a newbie, I figure I need to study Lego gear pairing. The screenshot below shows what I did in LDD. The objective here is simple; to see how various pair of gears can be positioned, since Lego designing is generally constrained by the number and position of the studs and holes of Lego bricks. So, I tried out a few combinations and roughly got the idea. I also found the site that helps in Lego Technic gear pairing.

Pic 1: Gear pairing exercise

Next step, I went straight to designing my gearbox. By the way, if you need to understand how gearboxes work, refer to How Stuff Works or here for Lego gears tutorial.

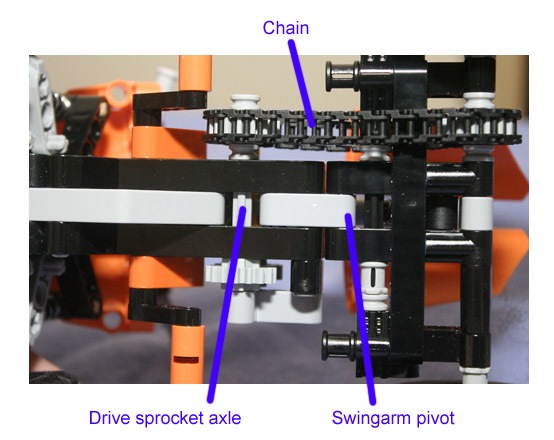

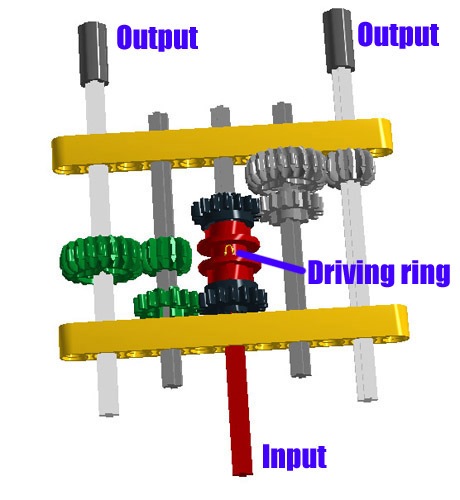

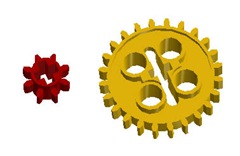

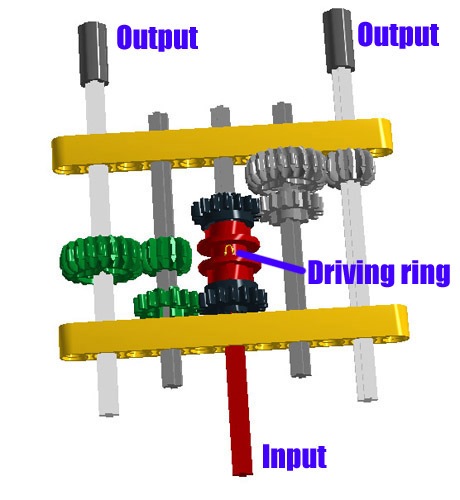

The screenshot in Pic 2 below shows what I did. I decided to lay it flat first, in order to see how the gears would be arranged and linked. As I've mentioned, I don't want gear grinding during shifting, so I use the driving ring that allows me to lock on to either one of the free wheeling gears.

Pic 2: The gearbox, flat

Basically, the gearbox provides a gear down from a 12 teeth gear to a 20 teeth gear (1:667) shown with green gears and a gear up from 20 teeth to 12 teeth gear (1:0.599) shown with grey gears. Because my design is laid flat, with very little effort you can trace the gear and axle movement of each speed setting, as shown in Pic 3.

Pic 3: Gear one and gear two

Now I know what I needed, next would be to simplify the design. Just like most things in engineering or computer programming, some components can be reduce, reuse or shared. After a bit of fiddling, I got this:

Pic 4: My two-speed gearbox

Pic 5: My two-speed gearbox, bottom view

Simply, the flat gearbox is ‘folded’ so that the gears and axles are layered. I've also combined the output axle, and made it compact. And just like that, I've completed my task. I’ve designed a two-speed gearbox. I can now go and watch The Big Bang Theory.

But I didn't.

This is too simple and too easy. I also looked at my gear ratios and it was clearly unrealistic.

If I can make a two-speed gearbox, surely I can make a four-speed version. The simplest thing to do is just to replicate my two-speed gearbox, and change the gear pairing to have different ratios. And that's exactly what I did.

Pic 6: Two two-speed gearbox

Now, the available gear ratios are:

| 1st gear 1:3 |  |

| 2nd gear 1:1.667 |  |

| 3rd gear 1:1 |  |

| 4th gear 1:0.599 |  |

But by having two two-speed gearbox, I now have two input and two output axle. So, the simplification cycle starts again. With a little rearrangement, and a few extra gears, Pic 7 is what I got:

Pic 7: Final four-speed gearbox

The final design fulfills all my requirement. It's a 4 speed, 1 input, 1 output, absolutely no grinding while changing gears. Can’t wait for my Lego Technic parts to arrive!

Am I done? Yes for now, but I can see a lot of gaps in my design. I'm sure seasoned Lego Technic designers would take one look at this, smirk and point out what I should have done. And I hope they do, so please, share your thoughts.

- Wan Khairil Reza -